|

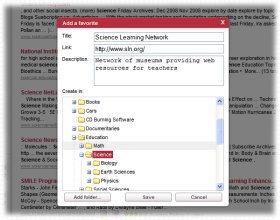

Web

Education

Abrasive wear test is done in four different points [7]. Abrasi Wear Tool with OgoshiMethod Speciment after Abrasive Wear Test Figure 3.Tool and Speciment of Abrasive Wear Test [13]. THEORY Bucket teeth (teeth or also called bucket claws) is the part of bucket teeth, the component which frequently gets...

Abrasive wear and its application to digger teeth ...

Mashloosh and Eyre - abrasive wear of digger teeth Laboratory wear evaluation The steels of different compositions in Table 3 were cast as keel blocks by the Steel Castings Research and Trades Association and analysed by a spectrographic technique. A commercial digger tooth was also supplied for examina- tion....

Abrasive Wear of Digger Tooth Steel - CORE

The influence of silicon carbide SiC abrasive particles of 20, 30, 40, 50 and60μm size on carburized digger tooth steel was studied. Four types of steel, withdifferent hardness, were tested at two constant linear sliding speeds and undervarious loads of 10, 20, 30, 40 and 50N. Tests were carried out for sliding time of0.5, 1.0, 1.5, 2.0 and 2 ......

Analysis of AISI material power of AISI 4140 bucket teeth ...

They are the digger machines normally used for dredging materials in mine, digging, leveling the ground, dredging the river, etc. One of the components of excavator that is frequently replaced is bucket teeth. The replacement of bucket teeth is mainly due to the wear factor occurring in this component.

Analysis of AISI material power of AISI 4140 bucket teeth ...

The effect of Ti addition (0.15 and 0.20 wt%) on mechanical properties and wear resistance of steel excavator bucket teeth was investigated. Teeth were produced by commercial sand casting technique.

Analysis of AISI material power of AISI 4140 bucket teeth ...

Excavators are often used in the mining and construction projects. They are the digger machines normally used for dredging materials in mine, digging, leveling the ground, dredging the river, etc. One of the components of excavator that is frequently replaced is bucket teeth. The replacement of bucket teeth is mainly due to the wear factor occurring in this component.

Title: Abrasive wear with particular reference to digger teeth

Digger teeth can be produced in different shapes and sizes (mainly by casting) and a wide range of materials are used. This project is concerned with both a field trial of the wear of digger teeth fixed to the front of a bucket used in a gravel pit, and also a laboratory investigation of abrasive wear mechanisms....

Materials selection to excavator teeth in mining industry ...

Tooth wear is tracked over a 6-day period and wear rate statistics are computed for 6 teeth. This validates the system and provides an example of how wear patterns can be recorded and analysed by ...

Abrasion, Wear Life, Costs Factor in the Hard Facing ...

What do buckets, teeth, moldboards, dozer blades, shears, and even grousers all have in common? Contact with the ground is only partially correct. They all contact the ground with possible abrasion, and it’s the level of abrasion, the desired wear life, and the cost of new ground-engaging tools that determine whether hard facing is a maintenance option. Hard facing is the application, by ......

Volvo Tooth System

The teeth have the correct balance between hardness and high tension steel, which is the key to quality and long wear-life. The Volvo Tooth system also includes segments and wear caps in several sizes to extend the lifetime of your bucket and adapter. Volvo has a wide range of teeth, adapters and segments for Wheel loaders and Excavators....

|